DRY ICE Cleaning

Dry ice cleaning, also known as dry ice blasting or CO2 blasting, is a non-abrasive cleaning method that uses dry ice pellets to remove contaminants from surfaces. It is a safe and environmentally friendly alternative to traditional cleaning methods that involve chemicals, water, or abrasive materials.

Dry ice cleaning works by propelling dry ice pellets at high speeds onto the surface to be cleaned. The dry ice pellets immediately sublimate upon impact, converting from a solid to a gas. This process creates tiny explosions that lift away the dirt, grime, or contaminants from the surface, leaving it clean.

One of the main advantages of dry ice cleaning is that it does not produce secondary waste. Since the dry ice pellets sublimate into gas, there is no residue left behind. This makes it ideal for cleaning delicate or sensitive equipment, as there is no risk of damage from water or abrasive materials.

Dry ice cleaning is also a versatile method that can be used in various industries and applications. It is commonly used in industrial settings for removing grease, oil, paint, adhesives, and other stubborn contaminants from machinery, equipment, and surfaces. It is also used in the food industry for cleaning ovens, conveyor belts, and other food processing equipment.

Some benefits of dry ice cleaning include:

1. Non-abrasive: Dry ice cleaning is gentle on surfaces and does not cause any damage or wear. It can be used for many materials such as metal, plastic, rubber and wood.

2. Environmentally friendly: Dry ice is made from recycled carbon dioxide, a byproduct of other industrial processes. It does not produce any harmful chemicals or contribute to air pollution.

3. Safe: Dry ice cleaning does not involve the use of chemicals or water, making it safe for operators and the environment. It also eliminates the need for manual scrubbing or abrasive materials, reducing the risk of injuries.

4. Efficient: Dry ice cleaning is a fast and efficient method. It provides cleaning by entering gaps and hard-to-reach areas. It also reduces downtime since equipment can be cleaned in place without disassembly.

However, there are some considerations to keep in mind when using dry ice cleaning. The process generates carbon dioxide gas, which can displace oxygen in enclosed spaces. Adequate ventilation and safety precautions should be taken to prevent inhalation. Additionally, protective gear, such as gloves and goggles, should be worn to protect against flying debris.

In conclusion, dry ice cleaning is a highly effective and versatile cleaning method that offers numerous benefits. It is safe, environmentally friendly, and can be used in various industries and applications. Whether you need to remove grease from machinery or clean food processing equipment, dry ice cleaning can provide a powerful and efficient solution.

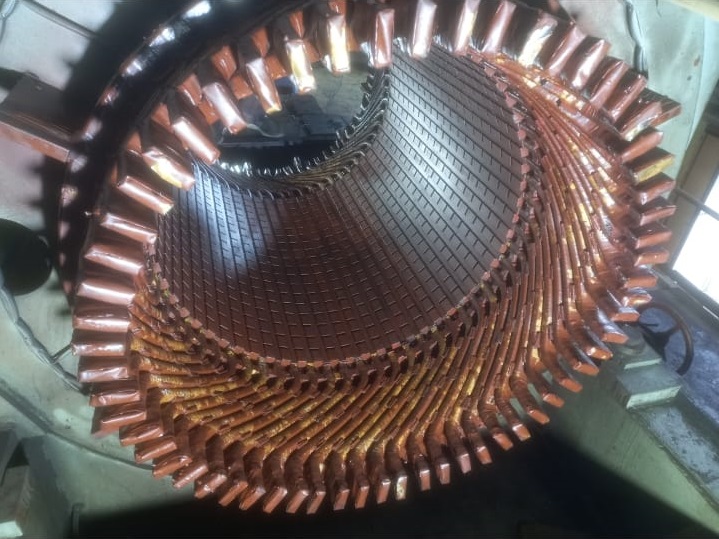

Alternator Before Dry Ice Cleaning

Alternator After Dry Ice Cleaning