DC Motor

Understanding the Dynamics of DC Motors: A Comprehensive Overview

Introduction:

Direct current (DC) motors have played a pivotal role in powering a wide array of devices and machinery for over a century. From simple household appliances to complex industrial systems, DC motors are ubiquitous in their application. This article explores the fundamental principles, types, and applications of DC motors, shedding light on the engineering marvel that drives countless aspects of modern life.

Basic Principles of DC Motors:

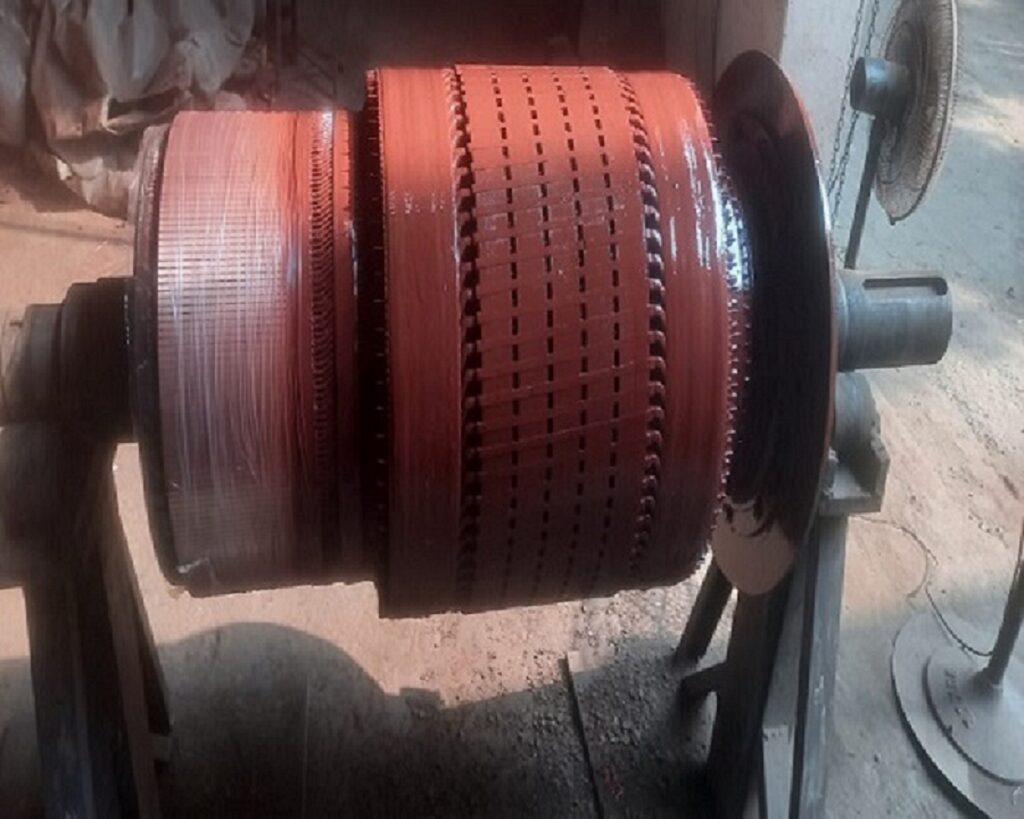

DC motors operate based on the principles of electromagnetism, where the interaction between magnetic fields and electric currents generates mechanical motion. The two primary components of a DC motor are the stator (stationary part) and the rotor (rotating part). The stator contains the field winding, which produces a magnetic field when current flows through it. The rotor, usually equipped with windings, experiences a force due to the interaction with the magnetic field, resulting in rotational motion.

Types of DC Motors:

Brushed DC Motors:

In brushed DC motors, a commutator and brushes are used to reverse the current direction in the rotor windings, ensuring a continuous rotation.

Despite their simplicity, brushed DC motors suffer from issues like brush wear, sparking, and limited lifespan.

Brushless DC Motors (BLDC):

BLDC motors eliminate brushes and commutators, reducing maintenance and enhancing efficiency.

Electronic controllers manage the timing and distribution of current to different windings, leading to smoother operation and increased reliability.

Permanent Magnet DC Motors (PMDC):

In PMDC motors, a permanent magnet is used in the stator, eliminating the need for a separate field winding.

These motors are compact, lightweight, and find applications in various portable devices.

Applications of DC Motors:

Automotive Industry:

DC motors power various components in automobiles, such as windshield wipers, power windows, and electric power steering systems.

Industrial Machinery:

DC motors are widely used in industrial applications, driving conveyor belts, pumps, fans, and other machinery.

Consumer Electronics:

Many household appliances, like blenders, vacuum cleaners, and electric shavers, rely on the simplicity and efficiency of DC motors.

Robotics:

DC motors play a crucial role in robotics, providing precise control for robotic arms, locomotion, and other movements.

Renewable Energy Systems:

DC motors are employed in renewable energy systems, such as wind turbines and solar trackers, where their efficiency and control capabilities are valuable.

Challenges and Future Developments:

While DC motors have proven to be reliable and versatile, ongoing research focuses on enhancing their efficiency, reducing energy consumption, and addressing environmental concerns. The integration of smart technologies, improved materials, and advancements in control systems contribute to the evolution of DC motors, ensuring their continued relevance in the rapidly changing landscape of technology.

Conclusion:

DC motors are the unsung heroes that power our everyday lives, from the smallest electronic gadgets to the most complex industrial machinery. Understanding the principles and applications of DC motors is crucial for engineers, researchers, and enthusiasts alike as we continue to rely on these devices for innovation and progress. As technology advances, so too will the capabilities of DC motors, shaping the future of automation, transportation, and beyond.