Commutators for DC Motors

DC motors are widely used in various applications, ranging from household appliances to industrial machinery. One crucial component of a DC motor is the commutator. In this article, we will explore the role of commutators in DC motors and their significance.

To understand the function of a commutator, we first need to grasp the basics of how a DC motor operates. A DC motor converts electrical energy into mechanical energy through the interaction of magnetic fields .It has two main parts: stator and rotor. The stator is the constant a part of the motor and the rotor is the rotating element.

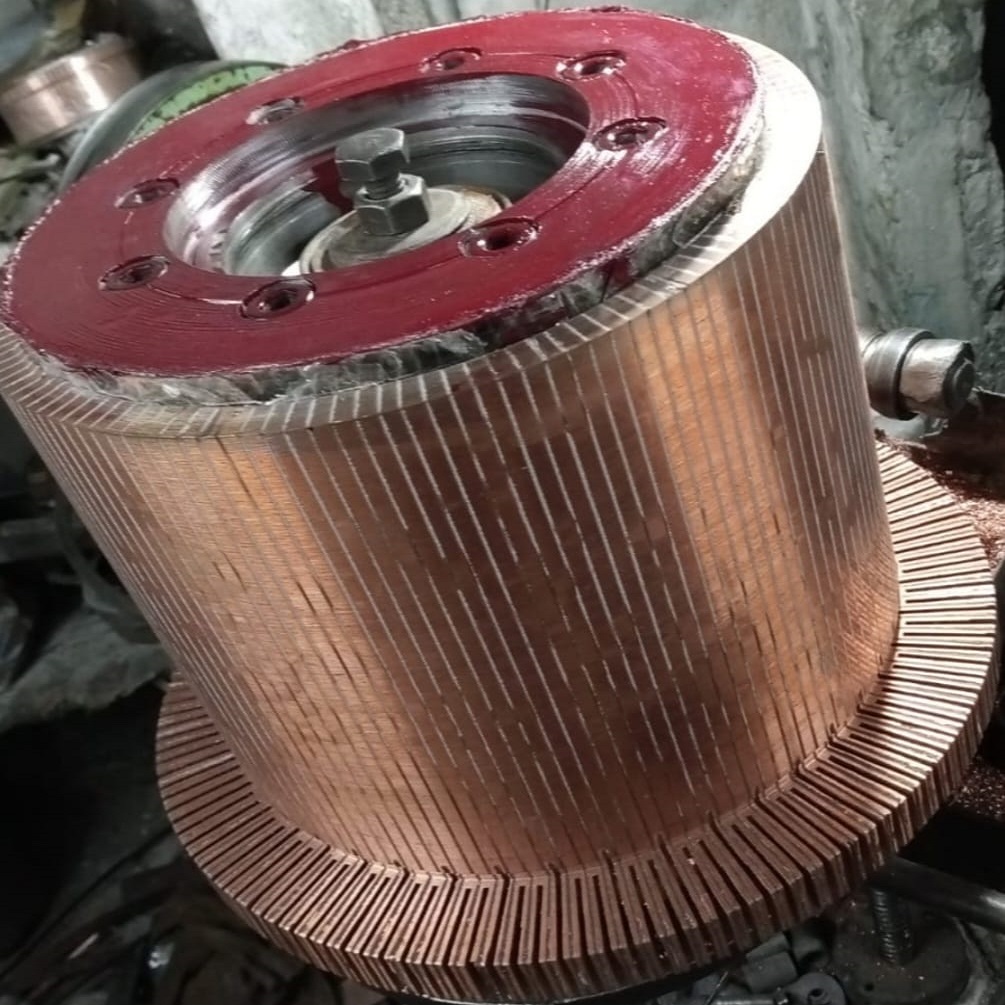

The commutator is a vital element within the rotor of a DC motor. It is a cylindrical structure made up of metal segments, typically copper, that are insulated from each other. These segments are connected to the armature windings, which carry the electrical current.

So, what is the purpose of a commutator? The commutator serves as a mechanical rectifier within the motor. Its primary function is to switch the direction of the current flowing through the armature windings, thus ensuring continuous rotation of the rotor.

When an electrical current is supplied to the motor, it creates a magnetic field that interacts with the magnetic field produced by the stator. This interaction generates a torque, causing the rotor to rotate. However, to maintain continuous rotation, the direction of the current in the armature windings must be periodically reversed. This is in which the commutator comes into play.

As the rotor spins, the commutator brushes, in contact with the metal segments, make electrical connections with the armature windings. These connections continuously switch the direction of the current flowing through the windings, allowing the rotor to keep rotating in the same direction.

The commutator also ensures that the current flows evenly through each segment of the armature windings. By providing a segmented structure, the commutator prevents the build-up of excess heat and distributes the electrical current evenly, optimizing the motor’s efficiency and performance.

It is worth mentioning that commutators require regular maintenance to ensure their proper functioning. Over time, the brushes and segments of the commutator can wear out due to friction and electrical arcing. Therefore, periodic inspections and cleaning are necessary to prevent any potential issues and extend the lifespan of the commutator.

Conclusion,

commutators play a crucial role in the operation of DC motors. By switching the direction of the current flowing through the armature windings, they enable continuous rotation of the rotor. Additionally, commutators ensure even distribution of the electrical current, contributing to the motor’s efficiency and performance. Understanding the function and significance of commutators is essential for anyone working with or maintaining DC motors.

Remember, proper maintenance and care of the commutator will ensure the smooth and efficient operation of your DC motor. So, keep an eye on this small yet vital component and ensure its longevity for optimal motor performance.